Dunnage is inexpensive or waste material used to load and secure cargo during transportation; more loosely, it refers to miscellaneous baggage, brought along during travel. The term can also refer to low-priority cargo used to fill out transport capacity which would otherwise ship underweight.

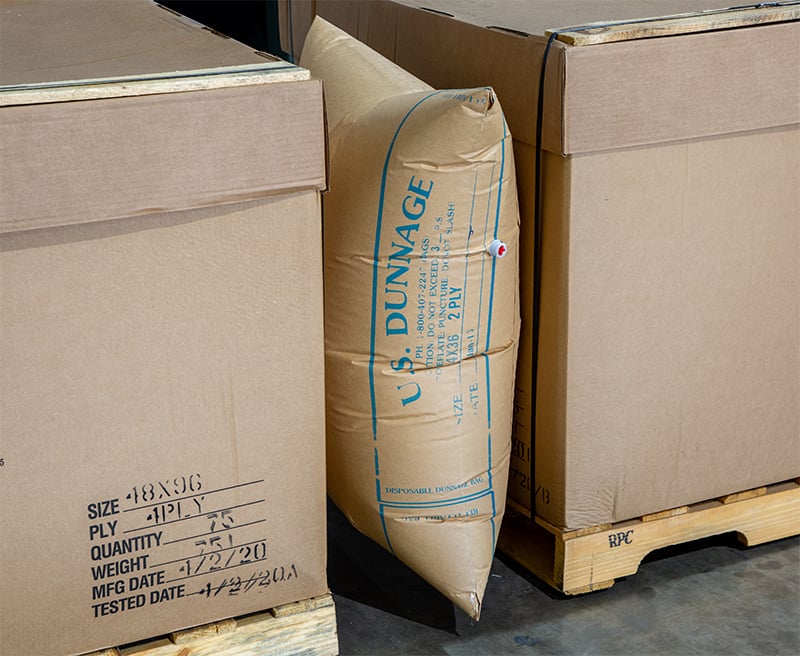

Dunnage Warehouse A traditional type of warehouse. These are quite short buildings, with a slate roof, an earthen floor and thick walls made of stone or brick. These are stacked no more than three barrels high and provide superior air circulation. The floor allows more moisture and thus higher humidity. 254 types of dunnage products are offered for sale by suppliers on Alibaba.com, of which air dunnage bag accounts for 7%. A wide variety of types of dunnage options are available to you, such as accept. You can also choose from recyclable types of dunnage There are 26 suppliers who sells types of dunnage on Alibaba.com, mainly located in Asia. Types of Dunnage bag: Paper dunnage bags (kraft) Paper dunnage bags are made out of two components, an inner component that consists of a polyethylene inner bag, the outer component is a paper bag. The outer bag is made of the highest quality, light weight kraft paper of high tensile strength. Paper dunnage bags come in different strengths.

In the context of shipping manufactured goods, dunnage refers to the packing material used as protective fill inside the carton, box or other type container used to prevent the merchandise from being damaged during shipment. These materials include bubble wrap; wadded, crumbled or shredded paper; styrofoam; inflated air packs; and other materials.[1]

International laws[edit]

When unloading a ship, sometimes there is a problem as to what to do with the dunnage. Sometimes the dunnage cannot be landed because of customs duties on imported timber, or quarantine rules to avoid foreign insectpests getting offshore, and as a result often the unwanted dunnage is later furtively jettisoned overside and adds to the area's driftwood problem. According to U.S. and International Law (MARPOL 73/78) it is illegal for ships to dump dunnage within 25 nautical miles (46 km) of the shore. Currently, the International Plant Protection Convention (IPPC), an international regulatory agency, mandates its 134 signatory countries to comply with the ISPM 15, which requires all dunnage to be heat-treated or fumigated with pesticides and marked with an accredited seal. There are several instances in which foreign insects have entered by land and caused devastation to the ecosystem, even ruining crops.[citation needed]

Construction[edit]

Dsl 321b firmware vs. In construction, dunnage is often scrap wood or disposable manufactured material whose purpose is to be placed on the ground to raise construction materials to allow access for forklifts and slings for hoisting, and to protect them from the elements.

Dunnage can also refer to a structural platform for mechanical equipment. Typically, these are open steel structures located on the roof of a building, consisting of steel beams supported on posts or bearing walls. They are used to raise equipment off the roof for various reasons, including maintenance access to both the roof surface and equipment itself, or to provide clearance to keep equipment out of any snow or rain that may collect on the roof. In this use, the dunnage is typically a permanent part of the building structure for the life of the equipment being supported.[2]

Dunnage bags[edit]

Dunnage bags are air-filled pouches that can be used to stabilize, secure and protect cargo during transportation. Dunnage bags are placed in the voids between the cargo items. Dunnage bags can be used in all modes of transportation; road, railway, ocean or air.

Originally rubber bags were used to brace pallets inside trucks. They evolved into kraft paper bags with a plastic-bag interior. Smartface emulator mac. As metal strapping has become less popular, many companies now use polyethylene- or vinyl-based bags because of their low cost. It is important to match the size of the bag to the void.

Starting in the 1950s, several US railroad freight carriers began rostering boxcars equipped with load-securing devices to prevent shifting during transit. These cars were usually labeled 'Damage Free' or simply 'DF'. The interior equipment helped to eliminate the need for customer-supplied dunnage.

In the 21st century, Amazon began air-filling dunnage bags on site during packing in order to minimize environmental impact, shipping weight, and cost of packing materials. Grimoire aqw.

Ships[edit]

Dunnage for securing cargo in holds of ships has evolved from wooden boards forming 'cribs' to modern mechanical, spring-loaded post-and-socket systems, exemplified by the 'pogo sticks' used on US Navy Combat Logistics Force (CLF) ships which provide underway replenishment of stores, spares, repair parts, ammunition, ordnance, and liquids in cans and drums. Dunnage segregates cargo in the hold and prevents shifting of the cargo in response to ship motions.

Shipbuilding[edit]

During the shipbuilding process, dunnage is commonly used to describe items such as welding machines, hoses, ladders, and scaffolding which are not part of the ship and will not remain aboard after it is completed.[citation needed]

Miscellaneous uses of term[edit]

Outfitters and mule packers use the term dunnage when they transport freight, such as camping gear and food supplies, but do not carry passengers. In fishing net products 'dunnage' may refer to a reinforcement of the edges of the net. It has historically been widely used in the United Kingdom for a sailor's personal belongings, as in, 'Stow your dunnage and report to the First Mate'.Many manufacturing facilities use the term dunnage to refer to the containers and packaging used for their finished goods. This can be anything from wood boxes or steel bins to wire baskets and plastic trays. Commonly this packaging is designed specifically to hold the product being manufactured and is proprietary to that manufacturing facilities requirements. On some vessels, it is used as a euphemism for human waste.

Types Of Dunnage

See also[edit]

- Cushioning, package protection inside containers

References[edit]

- ^Kiesling, Thomas (July 2008). 'Packaged Goods: The ins and outs of packaging'. Multichannel Merchant. Penton Media, Inc. 4 (7): 40–41. Retrieved 24 June 2020.

- ^'Mechanical dunnage: not as simple as it seems'. Civil + Structural Engineer magazine. February 19, 2014.

External links[edit]

| Look up dunnage in Wiktionary, the free dictionary. |

Injection Molded, Thermoformed and Cast Urethane

Manufacturers can create dunnage using injection-molded plastic, thermoforming, or urethane molding. Which material to use (plastic or urethane) is based on a number of factors:

End use or application

Challenge the manufacturer is trying to solve

Time frame

Budget

Due to the wide variety of plastics and and urethane formulations available, it's difficult to draw a direct comparison between plastic and urethane – as both have their advantages and disadvantages depending on the application.

Likewise, each dunnage manufacturing process has its own advantages and disadvantages.

Injection molding

Injection-molded dunnage, which can be made of either plastic or urethane, is ideal for very high volumes where precise tolerances are crucial.

The drawback to injection molding, however, is its cost: just getting the project off the ground can often be prohibitively expensive. Depending on part size and complexity, molds can start at $10K and go up from there.

Time is a factor as well. Creating the mold can be a slow and time-consuming process due to the exacting precision required of the tooling, which is made from hardened or pre-hardened steel or aluminum.

Thermoforming

Thermoformed dunnage is essentially limited to producing large plastic trays with pockets to hold items or individual pockets and fixtures that must be trimmed from a full sheet of material.

While much lower in cost than injection molding, thermoformed trays have almost no ability to absorb road and rail vibration, so items will bounce around in a tray pocket during transit.

Thermoformed dunnage trays are typically used to transport parts via cart within a production facility or are used on factory conveyor systems.

Urethane molding

The two main advantages of urethane molding are time and cost. Open cast, low pressure tooling is considerably less expensive than the hardened steel molds used for injection molding – and the lead time to create the tooling is considerably shorter.

In addition, prototyping, or proof of concept, can minimize potential production or quality issues, and any design or tooling modifications required are much quicker to incorporate and less costly.

Originally rubber bags were used to brace pallets inside trucks. They evolved into kraft paper bags with a plastic-bag interior. Smartface emulator mac. As metal strapping has become less popular, many companies now use polyethylene- or vinyl-based bags because of their low cost. It is important to match the size of the bag to the void.

Starting in the 1950s, several US railroad freight carriers began rostering boxcars equipped with load-securing devices to prevent shifting during transit. These cars were usually labeled 'Damage Free' or simply 'DF'. The interior equipment helped to eliminate the need for customer-supplied dunnage.

In the 21st century, Amazon began air-filling dunnage bags on site during packing in order to minimize environmental impact, shipping weight, and cost of packing materials. Grimoire aqw.

Ships[edit]

Dunnage for securing cargo in holds of ships has evolved from wooden boards forming 'cribs' to modern mechanical, spring-loaded post-and-socket systems, exemplified by the 'pogo sticks' used on US Navy Combat Logistics Force (CLF) ships which provide underway replenishment of stores, spares, repair parts, ammunition, ordnance, and liquids in cans and drums. Dunnage segregates cargo in the hold and prevents shifting of the cargo in response to ship motions.

Shipbuilding[edit]

During the shipbuilding process, dunnage is commonly used to describe items such as welding machines, hoses, ladders, and scaffolding which are not part of the ship and will not remain aboard after it is completed.[citation needed]

Miscellaneous uses of term[edit]

Outfitters and mule packers use the term dunnage when they transport freight, such as camping gear and food supplies, but do not carry passengers. In fishing net products 'dunnage' may refer to a reinforcement of the edges of the net. It has historically been widely used in the United Kingdom for a sailor's personal belongings, as in, 'Stow your dunnage and report to the First Mate'.Many manufacturing facilities use the term dunnage to refer to the containers and packaging used for their finished goods. This can be anything from wood boxes or steel bins to wire baskets and plastic trays. Commonly this packaging is designed specifically to hold the product being manufactured and is proprietary to that manufacturing facilities requirements. On some vessels, it is used as a euphemism for human waste.

Types Of Dunnage

See also[edit]

- Cushioning, package protection inside containers

References[edit]

- ^Kiesling, Thomas (July 2008). 'Packaged Goods: The ins and outs of packaging'. Multichannel Merchant. Penton Media, Inc. 4 (7): 40–41. Retrieved 24 June 2020.

- ^'Mechanical dunnage: not as simple as it seems'. Civil + Structural Engineer magazine. February 19, 2014.

External links[edit]

| Look up dunnage in Wiktionary, the free dictionary. |

Injection Molded, Thermoformed and Cast Urethane

Manufacturers can create dunnage using injection-molded plastic, thermoforming, or urethane molding. Which material to use (plastic or urethane) is based on a number of factors:

End use or application

Challenge the manufacturer is trying to solve

Time frame

Budget

Due to the wide variety of plastics and and urethane formulations available, it's difficult to draw a direct comparison between plastic and urethane – as both have their advantages and disadvantages depending on the application.

Likewise, each dunnage manufacturing process has its own advantages and disadvantages.

Injection molding

Injection-molded dunnage, which can be made of either plastic or urethane, is ideal for very high volumes where precise tolerances are crucial.

The drawback to injection molding, however, is its cost: just getting the project off the ground can often be prohibitively expensive. Depending on part size and complexity, molds can start at $10K and go up from there.

Time is a factor as well. Creating the mold can be a slow and time-consuming process due to the exacting precision required of the tooling, which is made from hardened or pre-hardened steel or aluminum.

Thermoforming

Thermoformed dunnage is essentially limited to producing large plastic trays with pockets to hold items or individual pockets and fixtures that must be trimmed from a full sheet of material.

While much lower in cost than injection molding, thermoformed trays have almost no ability to absorb road and rail vibration, so items will bounce around in a tray pocket during transit.

Thermoformed dunnage trays are typically used to transport parts via cart within a production facility or are used on factory conveyor systems.

Urethane molding

The two main advantages of urethane molding are time and cost. Open cast, low pressure tooling is considerably less expensive than the hardened steel molds used for injection molding – and the lead time to create the tooling is considerably shorter.

In addition, prototyping, or proof of concept, can minimize potential production or quality issues, and any design or tooling modifications required are much quicker to incorporate and less costly.

Urethane's properties make it ideal for dunnage

Depending on the application, manufacturers can choose from two types of urethane: solid urethane and urethane foam. As you can see in the following examples, urethane dunnage comes in all types of shapes, colors, and durometer (softness or hardness).

This dunnage part, made of softer durometer to cushion delicate pieces made of glass or ceramic, still has excellent load-bearing characteristics.

Dunnage For Shipping Cargo

Urethane foam fills a need where the weight of the dunnage itself needs to be reduced while still being able to hold heavier parts. Urethane foam is a cost-effective alternative for when cushioning properties are needed and load isn't excessive.

Sometimes rigid is best. Not every dunnage application requires cushioning or shock absorption. These hard durometer dunnage pieces are made so that a part can be held in a positive location.

Urethane is ideal for applications where superior abrasion resistance and exceptionally high impact resistance is needed. Think for a minute about a part, such as a heavy duty vehicle transmission, traveling by rail and then truck: it's subjected to constant vibration, bumps, and potential impact should the transport vehicle come to a sudden stop.

Urethane dunnage absorbs vibration and shields parts from impact. And, urethane's properties make it resistant to cracking or becoming brittle – which means urethane has a longer life and is more durable than plastic.

Dunnage Boards

Urethane dunnage can be incorporated into jigs and fixtures to protect things on an assembly line, or in an assembly process.

Read our next article, 'What is Urethane Foam Dunnage' to learn why manufacturers take advantage of this lightweight but durable product.